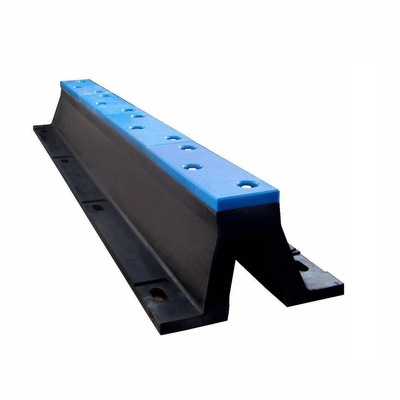

Customizable Geometry and Pressure

Each fender can be engineered with specific diameter, length, and air pressure tailored to vessel hull shape, berthing velocity, and structural requirements. This allows precise energy absorption and reaction force control for complex or non-standard applications.

High Performance Energy Management

The pneumatic design allows engineers to adjust internal air pressure to optimize energy absorption for high-speed or heavy-impact berthing scenarios. This ensures minimal stress on both vessels and quay structures, even under irregular operating conditions.

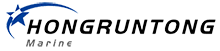

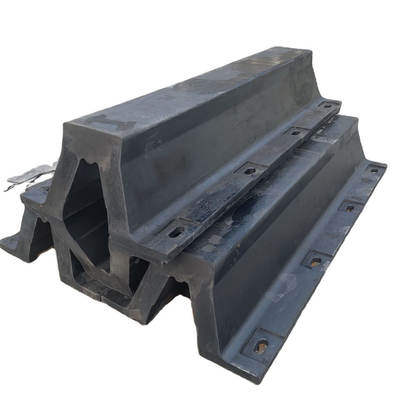

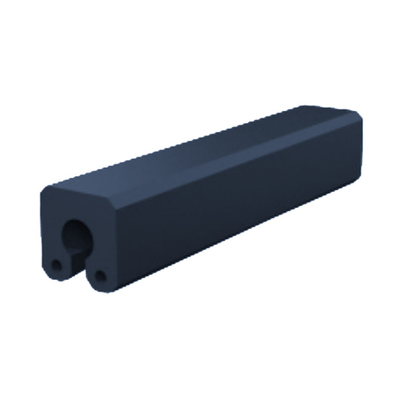

Durable, Abrasion Resistant Construction

The reinforced rubber surface withstands repeated friction, mechanical impact, and environmental degradation. Even under high-frequency or high-stress operations, the fender maintains performance and protects both vessels and infrastructure.

Operational Flexibility in Confined Spaces

The fenders’ flexible design allows deployment in limited dock areas, narrow berths, or unconventional berthing angles. This versatility is particularly valuable in custom projects, retrofits, or challenging port layouts.

Applications

Custom High Speed Ferry Docking

Designed for ferries or passenger vessels with non-standard hull shapes or high approach speeds, these fenders reduce hull stress and reaction forces while ensuring smooth berthing.

Specialized Offshore Operations

Used in custom offshore engineering projects, such as temporary floating platforms or subsea construction vessels, where standard fenders cannot provide adequate protection under dynamic conditions.

Unique Port Layouts and Retrofitting

Ideal for ports or shipyards with irregular berthing angles, narrow spaces, or legacy infrastructure requiring tailored fender solutions to maintain operational safety and efficiency.

Why Choose Hongruntong Marine

Expertise in Custom Marine Solutions

Hongruntong Marine specializes in designing and delivering bespoke fender systems for projects with unique operational or environmental challenges. Our engineering team collaborates closely with clients to tailor solutions for maximum safety and efficiency.

Flexible Engineering and Performance Optimization

We provide fully customizable fender configurations, adjusting dimensions, internal pressure, and reinforcement layers to meet specific project requirements, ensuring optimal performance under challenging conditions.

High Quality Materials and Reliability

All Yokohama Rubber Fenders are manufactured to strict quality standards, ensuring structural integrity, abrasion resistance, and long-term reliability, even for specialized applications.

Comprehensive Support for Unique Projects

Hongruntong Marine offers end-to-end support, including engineering consultation, installation guidance, maintenance planning, and operational training, ensuring smooth implementation and reliable operation of custom fender systems.

FAQ

1. Can these fenders be designed for unusual vessel hull shapes?

Yes, they can be fully customized in diameter, length, and air pressure to conform precisely to the hull geometry, ensuring even energy absorption and minimal hull stress.

2. Are they suitable for high-velocity berthing operations?

Absolutely. The internal pneumatic system allows adjustment of energy absorption characteristics to safely manage high-speed berthings without excessive reaction force.

3. Can the fenders be used in retrofitting projects?

Yes, they are highly adaptable and can be engineered to fit existing docks, piers, or offshore structures where space or design constraints exist.

4. What maintenance is required for custom fenders?

Routine visual inspection, air pressure monitoring, and surface cleaning are recommended. Proper maintenance ensures consistent performance even in demanding custom operations.

5. Do Hongruntong Marine fenders comply with safety and engineering standards?

Yes, all fenders meet international marine engineering and port safety standards. Custom projects are engineered to comply with relevant operational and structural requirements.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!