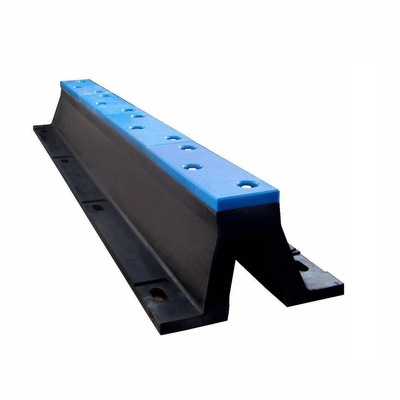

High Energy Absorption with Controlled Reaction Force

Hongruntong pneumatic fenders utilize optimized internal air pressure and geometric design to achieve a superior ratio of energy absorption to reaction force (EA/RF). This allows vessels to berth safely with minimal hull stress while maximizing impact mitigation. Laboratory and field tests demonstrate that even under repeated heavy berthing cycles, the fender maintains structural integrity and consistent performance.

Durable Multi Layer Reinforcement

The fender incorporates multiple layers of high-tensile synthetic tire cords arranged in cross-ply orientation, providing high resistance to internal pressure fatigue and preventing delamination. The design supports long-term exposure to cyclic loads without compromising structural integrity, ensuring service life exceeding 12 years under normal operating conditions.

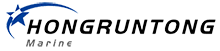

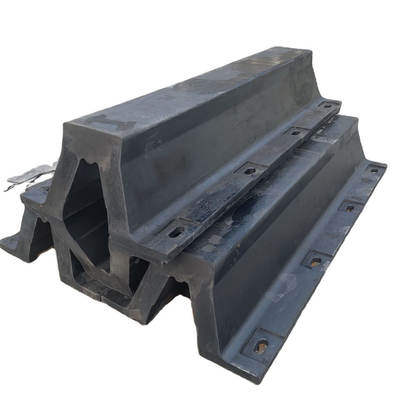

Integrated Tire Chain Protection Net

Each fender comes equipped with a modular tire-chain protective net that safeguards against abrasion from docking equipment, floating debris, or accidental vessel contact. The net allows quick replacement of individual tires, reducing downtime and maintenance costs.

Environmental and Operational Adaptability

The rubber compound is formulated for resistance against ozone, UV radiation, saltwater, and extreme temperatures ranging from –40 °C to +70 °C. Additionally, optional smart pressure monitoring systems enable remote performance tracking, early detection of pressure loss, and proactive maintenance planning.

Applications

Large Container Terminal Operations

Ideal for berthing high-frequency container vessels, pneumatic fenders provide high energy absorption and low hull stress, ensuring safe docking even during tidal variations or strong currents.

Offshore Floating Storage and Production (FPSO) Units

Suitable for dynamic offshore environments, the fenders maintain stability and cushioning for FPSOs and other floating platforms under wave action and variable loading.

Naval and Emergency Response Vessels

Provides reliable protection for rapid docking vessels, including coast guard and rescue ships, where safety, fast deployment, and durability are critical for emergency operations.

Why Choose Hongruntong Marine

Proven Engineering Expertise

With over 25 years in marine fender technology, Hongruntong offers precise engineering support including finite element simulations, dynamic modeling, and bespoke design solutions for varied maritime environments.

Rigorous Quality Control and Certification

All fenders are manufactured under ISO 9001 and ISO 14001 standards. Each unit undergoes hydrostatic testing, burst pressure testing, and ultrasonic inspection to meet ISO 17357-1:2014 requirements.

Global Service and Support Network

Hongruntong provides worldwide on-site installation supervision, maintenance services, spare parts logistics, and remote technical support via regional offices in Europe, Asia, and the Middle East.

Commitment to Sustainability and Safety

We employ eco-friendly rubber compounds and low-VOC adhesives. Integrated monitoring systems improve operational safety, reduce maintenance frequency, and contribute to environmental compliance for ports and offshore installations.

FAQ

Q1: What types of vessels can use pneumatic rubber fenders?

A: They are suitable for a wide range of vessels, including container ships, tankers, LNG carriers, naval ships, and emergency response vessels.

Q2: How long does installation take for a typical fender?

A: Installation time varies by size and mounting method, typically 2–5 days for a standard berth, with larger offshore installations requiring 1–2 weeks.

Q3: Can fenders withstand extreme temperature conditions?

A: Yes. The specially formulated rubber maintains flexibility and air retention from –40 °C to +70 °C.

Q4: Are pneumatic fenders reusable and portable?

A: Yes, deflated fenders can be transported compactly and redeployed as needed for temporary or seasonal operations.

Q5: What maintenance is required?

A: Regular pressure checks every six months for ports or quarterly for offshore applications, inspection of the tire-chain net, and replacement of any damaged tires.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!